Robotics Rebound

October 5, 2015

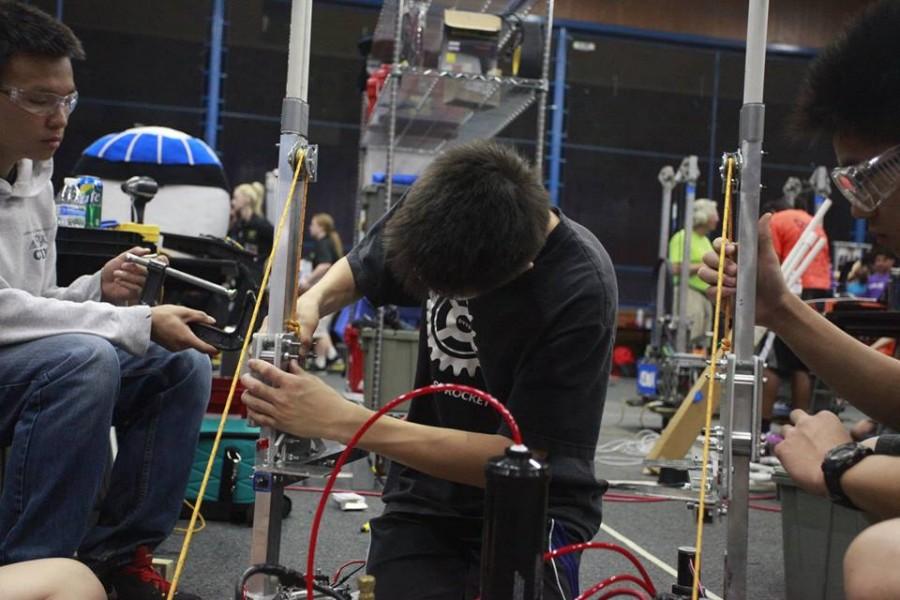

Having technical and mechanical malfunctions is a team’s worst nightmare, especially when their robot is in the middle of a competition. However, being able to recover and stabilize the robot in order to compete in the tournament the next day requires great skill. Team Sprocket was able to recover from that loss and place third overall during the second day of the off season Fall Classic competition.

“This competition led to great experiences for our incoming members because it was a great way to get a feel for how the team works and how we operate when it comes to competition. This competition meant everything for our members because they got to finally see their hard work paying off in the arena,” co-engineering captain Jonathan Ng said.

The objective of this year’s Fall Classic competition was to stack totes and recycle bins in designated areas around the course. Although it may not sound exciting, the robots required to stack the objects needed to fulfill specific parameters in order to obtain maximum effectiveness. The stacks wound up to be 12 feet high and within two minutes, over five of these 12 feet stacks were built within the course.

Stacking the boxes requires that the team be able to drive their robot using a controller, as well as use the robot’s functions to raise and lower the items. The robotics team used a double joystick control to drive the machinery along with a Logitech game controller in order operate the functions of the mechanism. Due to several mechanical, software, and field communication failures, the team had to forfeit some matches during the first day of Fall Classic, but came back strong the next day with their newly adjusted robot and team chemistry.

“Team Sprocket performed better than ever. We achieved new personal records and even stacked three sets of 5-totes in one match. We finished in third place, and our success can only be attributed to the dedication of our members, parents, mentors, and sponsors,” business captain Cathy Chang said.

Compared to last year, many aspects of Team Sprocket have improved by a large margin in regards to robot design, team efficiency, and business integration. The business section has secured many more sponsors, including financial and manufacturing sponsors that helps provide the team with money and materials for the construction of a robot.

While improvements from last year have been quite obvious, co-engineering captain, Forest Hu, continues to work on developing the team by cutting the members in half, from 40 to 20, in order to ensure that everyone will be dedicated and place robotics as one of their top priorities. Ng also wishes to improve the relationships with sponsors and potential mentors so that they can obtain professional guidance rather than struggle as a student led team.